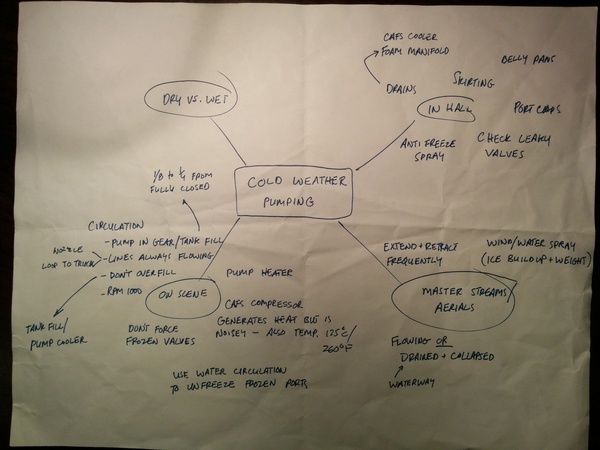

Cold Weather PumpingComment on this page

Cold Weather Operations (Waterous)

Raven

Cold Weather Pumping by Dennis Raven.pdf

23 Station Drill (Elvey)

Applies to -25C and similar weather

- Engage pump once on scene

- Open tank fill/recirculation (tank-to-pump must be open)

- Provides bigger flow than 5/8ths cooling lines/auxiliary cooling lines

- Tank-to-pump & pump recirculation are approx 65mm/77mm

- Anti-freeze caps @ beginning of shift and periodically during long calls

- Take note of ports that have water lying in them, this may indicate leaky ball valves

- Optionally run wet-to-port for discharges that have leaky ball valves (cannot run like this on 125 intake ports because they do not seal well enough)

- This must be communicated to crews coming on

- If running wet-to-port, close discharge when pumping & drain before attaching line

- Optionally circulate an extended hose line by temporarily removing the nozzle and running the output to an intake

Driver may ask hydrant to disengage the CAFs compressor for quieter running when waiting on-scene with no need to use CAFs. However, pump must be disengaged and re-enaged for CAFs to be used.

If you notice leaky ball valves earlier in the season (say August), it is better to report them to maintenance so they can be fixed in time rather than wait for the problem to become an issue in cold weather.

12 Station Drill (Adams/Croxall)

Dry pumping

Pros

- Minimal change pump will freeze

- Opportunity to ensure tank-to-pump & tank-fill valves are sealing

- Ideal for extended response distances

Cons

- Requires periodic opening of main drain to ensure pump cavity isn’t partially full of water (partially full pumps freeze rapidly causing potential for damage)

- If main pump drain is left open and tank-to-pump and/or tank fill valves are leaking, apparatus booster tank could be low/empty - requires constant monitoring & filling of the tank

- Drains can freeze in the open position

- Pumps left dry for extended periods

- Excessive build up of rust and/or calcium deposits may create problems with discharge relief valves, plug strainer screens, scoring to discharge valve seats, damage to discharge valve drains, priming valve, o-rings, seals on mating surfaces

- Priming may be required

Note: pumps are rarely completely dry!

Wet pumping

Pros

- Priming may not be necessary

- Mechanical seals/packing remain in water

- Keeps them pliable

- Reduces chances of calcium build-up

- Reduced chance of dry run conditions

Cons

- Chance of damage increases if pump is not engaged & water isn’t properly circulated

- Chance of freezing increases with excessive response distances & increased road speeds

- Potential for increase in repair costs

Drains

- Drains often fail to empty completely

- Drains located after or downstream of discharge valve ball & seal

- They are not exposed to water circulation!

- Never open main pump drain/discharge valve when under pressure - damage to o-rings/seals may occur resulting in a leaking drain valve

Last edited 2015-02-11 19:56 UTC by

Last edited 2015-02-11 19:56 UTC by ![[Twitter]](/img/twitter_box.png)

![[RSS]](/img/rss_box.png)