Nozzle ReactionComment on this page

Original article → Nozzle Reaction

By Author(s): Brian Bush

Published February 12, 2015 | Fire Engineering Blog

“Arguments for and against the use of various nozzle designs often become nullified on the fire ground as crews find they cannot safely operate lines which exhibit high nozzle reaction forces” Captain David P. Fornell

Nozzle Operating Pressure

The smooth bore nozzle may be viewed by some as “dated” by some but if you take a little deeper look at history you can see some very sound reasoning in the smooth bore nozzle. The operating pressure of the smooth bore is a range from 40 to 60psi, with 50psi as optimal. This was important to our forefathers in the fire service as early pump systems were primarily lower pressure and could see significant fluctuations with more than one line being supported simultaneously. The solid stream and long tip provided accurate delivery of the fire stream at a great distance for firefighters with limited PPE.

As technology advanced, our pumps were able to provide higher and more consistent pressures. Lloyd Layman and various others brought the fog nozzle into the American fire service, vendors started to develop automatic nozzles and before we knew it there was a shift from a 50psi fire service to 100.

Over the last 15 to 20 years an increasing number of firefighters and departments are beginning to question what has been gained by doubling our nozzle operating pressures. In many cases it is being discovered that for the most part the only true gain has been nozzle reaction which simply equates to more work on the nozzle firefighter.

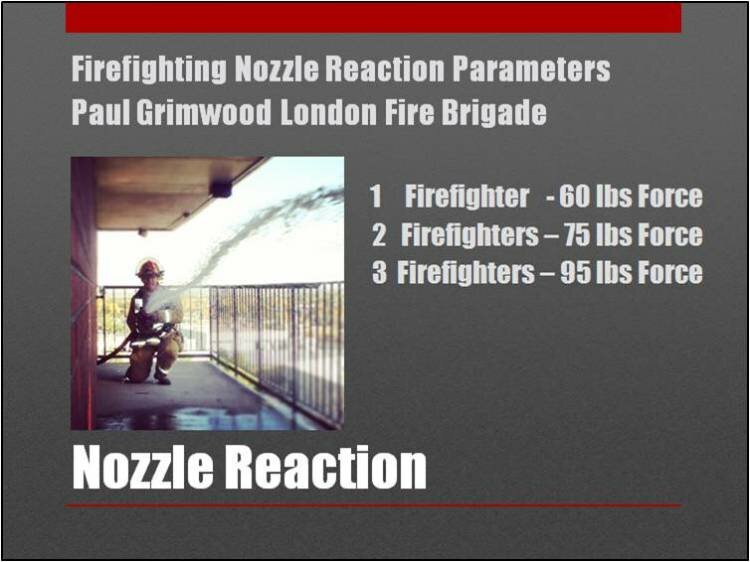

There have been several studies done over the last 20 years into nozzle reaction and how it effects hose line operations. The goal of these studies has been to identify how much nozzle reaction firefighters can comfortably handle while still being able to effectively advance and manage a hose-line. A study by Paul Grimwood outlined three working limits; 1 firefighter (60 force/lbs), 2 firefighters (75 force/lbs), and 3 firefighters (95force/lbs). I have been fortunate enough to work with firefighters across the country on hoseline operations and I can tell you that with good technique, practice, improved fitness and continued work, firefighters can easily operate lines with nozzle reaction forces beyond the above working limits. However, these working limits are very accurate for the majority of firefighters and the median level of training.

Nozzle reaction is the resultant pounds force push back of the combined volume and pressure leaving the nozzle. The only way to alter nozzle reaction is to alter the volume (GPM) or the pressure (PSI). Many people have used a variety of methods to demonstrate nozzle reaction like fish scales and rope but the actual force is calculated using the formulas below. As a rough rule of thumb the pounds force of nozzle reaction for a 100psi nozzle is ½ of the GPM.

Fog Nozzle Reaction

NR = .0505 Q √NP

NR (Nozzle Reaction)

Q = Gallons Per Minute

NP = Nozzle Pressure

Solid Bore Nozzle Reaction

NR = 1.57 D2 NP

NR (Nozzle Reaction)

D = Diameter of tip

NP = Nozzle Pressure

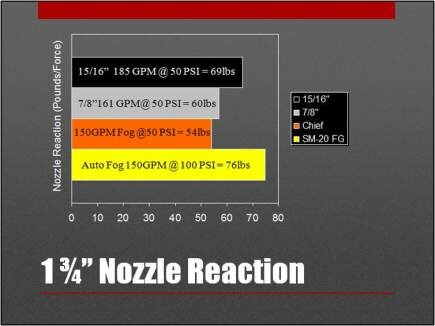

On this nozzle reaction chart we can see the amount of nozzle reaction associated with four very common 1 ¾” nozzles. You can also see the side by side comparison of a 150 GPM at 50psi fog with a 100psi automatic fog. Flowing the same GPM there is a nozzle reaction difference of 21 lbs. At 100 psi and 150 GPM the nozzle reaction of 76lbs is at the working limit of 2 firefighters. Here is where you need to question if your department sees this as necessary or unnecessary pressure.

With good practices and techniques, firefighters can work beyond the outlined nozzle reaction parameters above. Without those practices, nozzle reaction forces beyond 60lbs typically begins to reduce the effectiveness of the single firefighter nozzle operator.

This is a very important piece of the puzzle when purchasing equipment for the engine staffed with three. A three person engine company translates to a two member first due attack line. I have seen it time and time again where departments are training, purchasing and writing policy for staffing that they do not have.

If you have ever stretched a line from an engine to the second floor bedroom as the nozzle firefighter with only one other person you will discover instantly that you must learn to operate that nozzle without the luxury of a back up firefighter behind you to assist in countering nozzle reaction. The other member will almost always be working to tend the line through furniture, around corners and up stairs somewhere between your location and the front door.

If the 1 ¾” is your department’s “90% of the time” and your engine company staffing is three members, you must identify what your firefighters are comfortable with in regards to operating a line by themselves, it may be surprisingly less than you assume.

A Case Study in Nozzle Reaction and Function

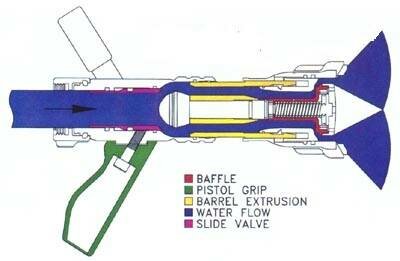

The advertised benefit of an automatic nozzle is a “wide operating range without stream compromise” Without getting too in-depth; this is achieved through an internal compensatory spring that adjusts with flow to maintain a constant nozzle pressure and steam. This type of nozzle essentially puts the flow rate in the hands of the pump operator and in the absence of a set department standard this becomes a very concerning unknown.

Our department primarily has 3 person engine staffing. In 2005 when we wanted to see if a nozzle study was needed at our department one of the first steps was to take 10 different engine companies, have them deploy and flow a 1 ¾” attack line and record the pump discharge pressure. At that time our department was using a 100psi automatic nozzle on all 1 ¾” attack lines. From the data collected we found that our average flow from these lines was 100 GPM. When the pump operators were asked why they pumped at their selected pressures almost all responses were not flow related, they were firefighter related. Nearly every operator stated they under pumped the lines initially to make it easier on the nozzle firefighter and they would increase the pressure if they called for more water.

Within this information is a very important finding. Our pump operators were acutely aware of the challenges of high nozzle reaction and they were attempting to address them for the nozzle firefighter hydraulically. Unfortunately in their good intentions is a risky business of not only under pumping (pressure) but by design also under supplying (volume) those firefighters entering the structure.

The idea that a firefighter “can always call for more water” comes from the known that an automatic has that wide flow range. The reality is that the stream quality is maintained throughout that wide flow range and the nozzle operator typically does not identify one lacking volume. Additionally the nozzle firefighter knows that requesting more water increases pressure, making for a more difficult line to manage. As you can see these contributing factors all conspire together and that “call for more water” never comes.

Using the average of 100 GPM from that 100 psi automatic fog nozzle and the fog nozzle reaction formula, we discovered that our firefighters and operators have subconsciously shown that a nozzle reaction of 50lbs is a comfortable point. Since nozzle reaction is dictated by a combination of pressure and flow so it serves as the perfect point in the discussion to bring the two together.

With the finding that our firefighters felt most comfortable handling about 50lbs of nozzle reaction we had a starting point. The next step was to determine a target flow for our 1 ¾” attack lines as it was clear from this initial test that we did not have one. For the goal of the study we wanted to establish 150 GPM as the minimum flow for any interior attack lines.

Why 150 GPM? Nationally, 150 GPM has become the target flow for 1 ¾” attack lines. This number comes from NFPA 1710 (Organization and Deployment of Fire Suppression Operations by Career Fire Departments). The standard outlines that the first two attack lines in operation at any residential structure fire flow a minimum of 300 GPM combined. With the NFPA wording you could flow 100 GPM with your initial line and 200 GPM with a second line but the common sense approach and now industry standard has targeted 150 GPM as an interior attack standard.

Utilizing nozzle reaction parameters and a set minimum standard for volume, the rest of the process is relatively simple; find nozzles that flow greater than 150 GPM with nozzle reactions near 60lbs and put them in the hands of firefighters for them to find their preference.

Common 1 ¾” Attack Line Nozzles and Reaction Force

| 150 GPM at 50 PSI Fixed Gallonage Fog | Nozzle reaction force of 54lbs |

| 7/8” Smooth Bore 161 GPM at 50 PSI | Nozzle reaction of 60lbs |

| 150 GPM at 75 PSI Fixed Gallonage Fog | Nozzle reaction force of 65lbs |

| 15/16” Smooth Bore 185 GPM at 50 PSI | Nozzle reaction force of 69lbs |

At the end of 2005, following a full year trail period with a variety of nozzles the preference of our firefighters was the 7/8” smooth bore with a flow of 161 GPM at 50 psi and a nozzle reaction of 60lbs. What is key to remember is that nozzle ratings are just “ratings”, when closed all nozzles flow 0. A 150 GPM or 2.5 gallon per second nozzle may seem “inferior” to one that flows 185 GPM or 3 gallons per second. If the nozzle firefighter can comfortably flow that 150 GPM nozzle for 30 seconds at a time around a corner while actively playing it they are delivering 75 gallons to the fire environment. A nozzle firefighter that is struggling with a 185 GPM or 200 GPM nozzle, only operating it for 10 to 15 seconds at a time without fatiguing, and has poor stream movement is potentially ineffectively applying only 30 to 50 gallons to the fire environment at a time. Put the right weapon in your operators hands, it may not be the one with the greatest fire power.

Last edited 2015-11-04 21:58 UTC by

Last edited 2015-11-04 21:58 UTC by ![[Twitter]](/img/twitter_box.png)

![[RSS]](/img/rss_box.png)